FOR 1660 - Optical Design and Interconnection Technology for Assembly-Integrated Bus Systems

©

pixabay.com

©

pixabay.com

Picture: Laser

Speaker:

Prof. Dr.-Ing. Jörg Ernst Franke

Friedrich-Alexander-University Erlangen-Nürnberg

The research group 1660 "Optical Design and Interconnection Technology for Assembly-Integrated Bus Systems" is dedicated to the investigation of processes and technologies for the design, construction and production of three-dimensional, optically functionalised mechatronic components (3D-opto MID).

Participating institutions:

- Friedrich-Alexander University of Erlangen-Nuremberg

- TU Dresden

- Leibniz University Hannover

- Laser Centre Hannover e. V.

Source: optaver.de

FOR 1845 - Ultra-Precision High Performance Cutting (UP-HPC)

©

pixabay.com

©

pixabay.com

Picture: Milling machine

Speaker:

Prof. Dr.-Ing. Ekkard Brinksmeier

University Bremen

The research group 1845 "Ultra-Precision High Performance Cutting" (UP-HPC) pursues the goal of reducing the disproportionately long main and secondary times in ultra-precision machining with scientific methods, in order to help this technology become economically viable in the manufacturing industry.

Beteiligte Institutionen:

- Leibniz-IWT

- Bremen Institute for Mechanical Engineering

- Institute of Production Engineering and Machine Tools

Source: up-hpc.de

FOR 2180 - Graded Implants for tendon- and bone junctions

©

Harlie Raethel on Unsplash

©

Harlie Raethel on Unsplash

Picture: X-ray image

Speaker:

Prof. Dr. Andrea Hoffmann

Hannover Medical School

The aim of the research group 2180 is to demonstrate the basic feasibility and exemplary production of a graded implant for future use at the tendon-bone transition of the rotator cuff. Electrospun fibre mats made of biodegradable polymers (in particular on the basis of polycaprolactone) with a directional ("tendon-side") or non-directional ("bone-side") fibre orientation serve as the basic material.

Beteiligte Institutionen:

Quelle: gradierte-implantate.de

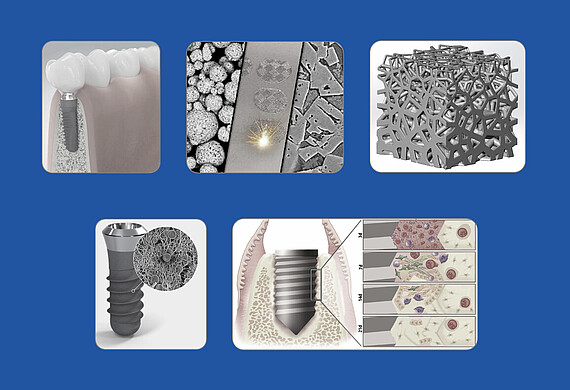

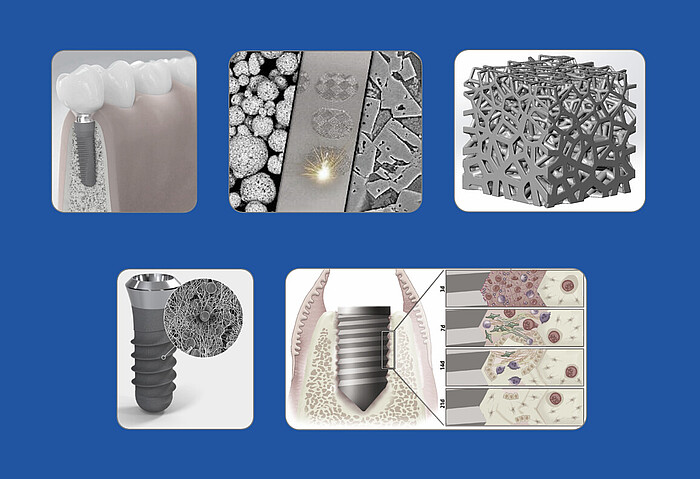

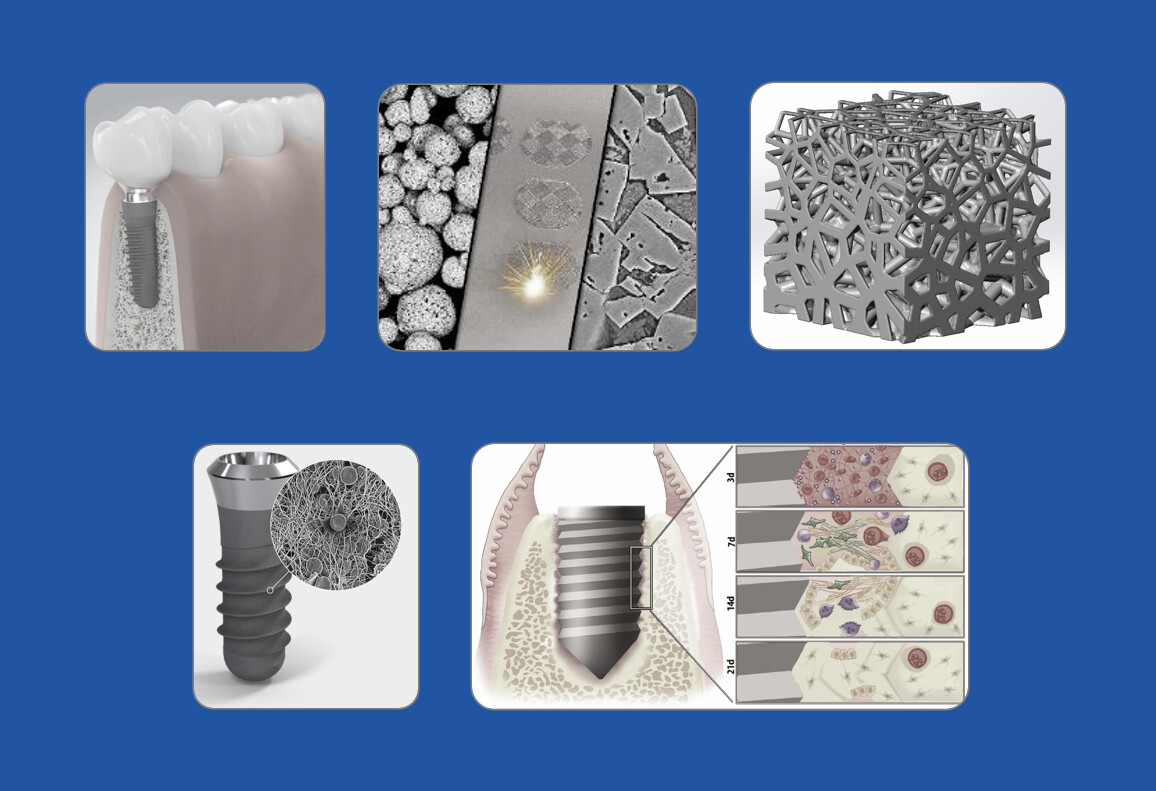

FOR 5250 - Mechanism-based characterization and modeling of permanent and bioresorbable implants with tailored functionality based on innovative in vivo, in vitro and in silico methods

Picture: Dental implant

Speaker:

Prof. Dr.-Ing. habil. Frank Walther

Char of Materials Test Engineering (WPT), TU Dortmund

Aim of the DFG research unit 5250 will be the development and validation of an integrated solution for the manufacturing, characterization and simulation-based design of additively manufactured implants in maxillofacial surgery, taking into account physiological conditions of the individual bone situation.

Beteiligte Institutionen:

- Laser Zerntrum Hannover

- Leibniz University Hannover

- Reutlingen University

- TU Dortmund

- Hannover Medical School

- Medical Center Hamburg-Eppendorf

- University Medicine Rostock

Source: for5250.mb.tu-dortmund.de